Infrastructure

As a pioneer PEB company in India, Devaj Engineering is equipped with the latest infrastructure and manufacturing facilities to deliver our customers the utmost solutions and services for constructing the best pre-engineering building structures. Our latest infrastructure includes

CNC Plasma Cutting Machine

We are pleased to present ourselves as one of the top producers, exporters, and suppliers of highly functional CNC plasma cutting machines. The provided machine, which is highly sought after in the automotive and fabrication industries, can cut any shape, including squares, ellipses, flanges, stars, circles, and more. Under the watchful eye of technocrats, this machine is produced utilising cutting-edge technology in accordance with accepted market standards. We offer this CNC Plasma Shape Cutting Machine in a variety of specifications at a competitive price to meet the various needs of our customers.

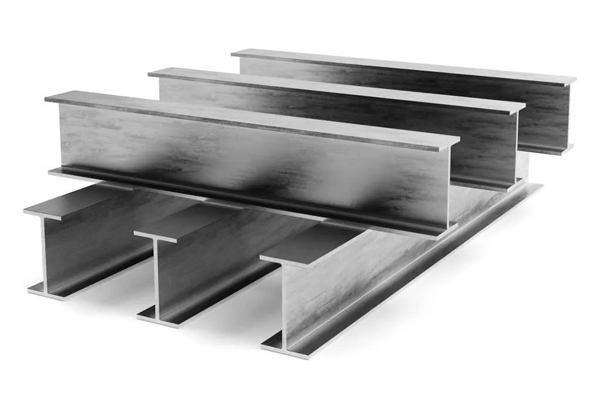

H Beam Welding Machine

H Beam Welding Machine is ideally used in the construction, manufacturing, and PEB industries for welding I-shaped and H-shaped beams used in steel structures such as bridges, buildings, railway stations, and other construction sites. This machine comprises components like a control system, welding heads, and clamping mechanisms.

It is useful in different welding processes based on the specific project requirements. The gantry design of the machine enables efficient and stable welding of H beams by giving equal pressure and alignment throughout the process. Thus, it improves the quality of welding processes and makes them secure, consistent, and efficient, which increases the proficiency and productivity of the manufacturing unit. Hence, this machine is highly beneficial for PEB industries.

Blasting Booth

In the PEB industry, a blasting booth is used for surface preparation, like removing rust, cleaning, and coating applications. It helps remove impurities from metal surfaces using abrasive materials that ensure clean smooth finishes. The blasting booths provide a regulated environment necessary for removing useless materials from PEB components, and steel beams and ensure safety by lowering environmental impact. It gives uniform surface preparation essential for the best quality control. Thus, a blasting booth is a beneficial infrastructure in PEB manufacturing for enhanced performance and cost-effectiveness.

Lifting equipment is best applicable for carrying and transporting heavy steel structures and components during assembly and construction. They are ideally used in moving heavy materials, large steel structures, and other parts efficiently and safely. The significance of using lifting equipment in the PEB industry is to reduce material damage during assembly or transportation and enhance the quality through the processes. The key benefits of using lifting equipment in PEB construction are to enhance the construction speed and safety as well as offering cost-effective solutions.

Overhead Cranea

An overhead crane is one of the most essential equipment for the PEB company. It is necessary to lift and transport heavy components such as steel structures, beams, and other parts in the manufacturing unit. It simplifies the process to handle large structures across the production floor and makes assembly times fast, enhancing operational efficiency, and safety of workers. This crane enables accurate positioning of structures, components, or materials during fabrication. Thus, with efficient material handling processes, it reduces downtime and increases the productivity of the manufacturing unit.

Hydra

Hydra cranes are popularly used in various industries for their robust design, versatility, and assorted applications. The key application of this crane in the construction industry is to lift and move heavy material at precise locations. This comprises steel structures, components, beams, and other materials for the PEB manufacturing company. It is also helpful in structural erection applications like bridges, buildings, complexes, and other infrastructure. They can efficiently extend the boom to great heights and enable the structural elements’ accurate positioning. Thus, it reduces the manual handling accident risks, and the possibility of damaging materials makes material handling processes efficient and cost-efficient.

Modern drilling equipment enables accurate holes in steel components for structural connections during the erection or assembly processes. They ensure accurate fittings, precise alignments, and load distribution and maintain the stability and integrity of the structure. With an accurate and speedy drilling process, they reduce the labor of workers, and error possibilities and increase the safety of workers. Thus, they streamline the assembly and production processes and reduce the cost and timeliness of the project.

Broach Cutter

The broach cutter cut slots, grooves, or intricate shapes. The sharp cutting teeth sequence of broach cutters is designed to create holes with high precision and surface finish with minimum wastage of material and utmost efficiency. Even shaping profiles or enlarging holes in steel or other metal materials, the broach cutter provides smooth, accurate, and consistent outcomes. They are widely used in metal fabrication and heavy-duty drilling in pre-engineering construction and infrastructure projects.

Bench Drill

The key application of bench drilling is pinpoint and precise drilling. It provides accurate depth adjustment and hence, is most suitable for applications where detailing is essential. It is vital for its different uses in PEB industries for creating bolt holes, pilot holes, and drilling holes for fastening PEB components such as beams, plates, columns, and other structural parts. Drilling equipment like bench drills makes the production process accurate, fast, and efficient by reducing manual work and the risk of inaccuracies. For PEB fabrication, they provide cost-effective and precise drilling solutions.

For more information about our top-quality services and solutions, write to us at info@devajeng.com or call us at +91 97129 73314